A Better Technology for Heat Transfer

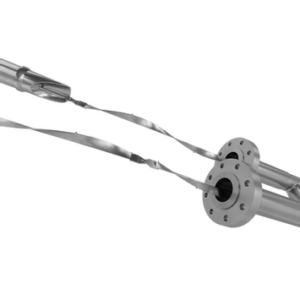

Our latest innovation, Xtend is a tube-insert to reduce fouling and increase heat transfer in fired heaters.

The Xtend technology generates more swirl with less pressure drop when compared to a conventional twisted tape. Less than 3% of the flow area is used to generate swirl.

The swirling flow:

- Cools the film on the tube wall

- Removes coke precursors from the film

- Increases both temperature and process uniformity within the tube

REDUCE

FOULING

REDUCE TUBE METAL

TEMPERATURE

EXTEND

RUN LENGTH

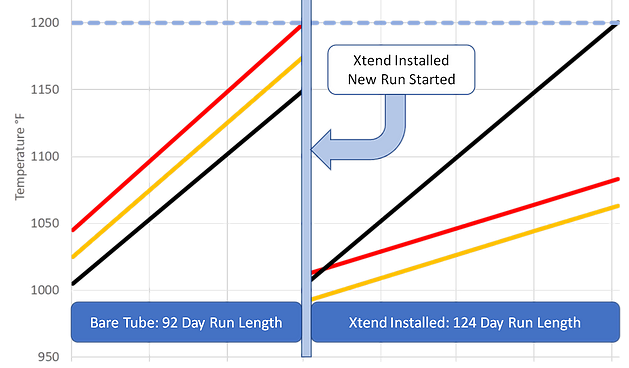

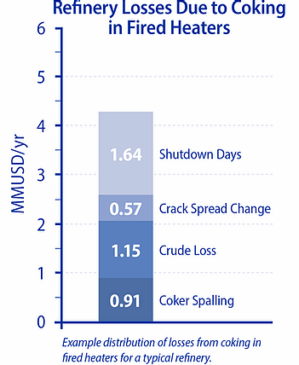

FIRED HEATERS FOULING COSTS MILLIONS

A typical 100,000 barrel per day refinery loses $3-7 million annually because of fouling in fired heaters. Fouling overheats tubes, increases firing rate, reduces yields, and causes lost onstream days. Shutting down a crude, vacuum, or coker heater is extremely costly both in labor and throughput.

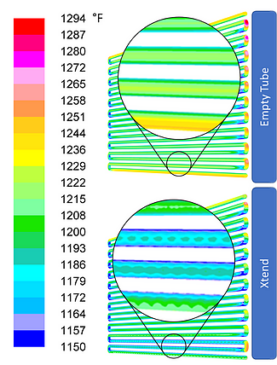

A multi-phase CFD simulation of an empty tube (left) and a tube with Xtend inserts (right) shows how Xtend reduces tube metal temperature and eliminates flow stratification inside a heater tube.

Xtend inserts can be used to reduce tube metal temperatures, reduce or eliminate internal fouling, and increase run-length.

XTEND SYSTEM COMPONENTS

Hover over this image to check out our components.

SMART APPLICATION

To minimize pressure drop while maximizing run length, Xtend only needs to be installed in the limiting tubes. The removable design does not engage with an end-of-run coke layer. If more coke builds up, Xtend inserts will flex in response, allowing for insert removal.

Over 97% of the tube remains open in a typical application, resulting in a low probability for additional coke blockage during spalling.

REDUCE TUBE METAL TEMPERATURE AND FOULING

In coker unit heater simulations, the Xtend system reduces the tube wall temperature by as much as 33° F. Lower film tempera-ture and increased bulk flow uniformity result in up to 3x less coking in tubes equipped with Xtend.

Simulations show similar benefits for other services — including crude, vacuum, and pyrolysis heaters. By fixing a few problematic tubes, we can unlock the full potential of your heater.