PATENT PENDING HEATER TECHNOLOGY

Do you want to reduce emissions from your fired heater? Do you desire increased capacity but fear poor flame quality or flame impingement due to increased firing rates?

To mitigate these issues, XRG developed the Xceed system to dramatically lower NOx and improve heat transfer.

The Xceed system allows the heater to be pushed much harder than what is possible with conventional burners alone. Xceed nozzles enable the use of high preheated combustion air temperatures, without exceeding your NOx limits, allowing increased heater efficiency and lower CO2 emissions. The system is compatible with alternative fuels, allowing for up to 100% CO2 reduction and SCR-level NOx.

The flexible Xceed system can be easily retrofitted to existing heaters and allows for operation with zero-to-100% dispersed combustion for maximum reliability.

VPR ENERGY PROJECT HIGHLIGHT

XRG successfully installed the Xceed System in VPR Energy’s heater in Rotterdam, Netherlands.

While Vitol’s main goal was to reduce hot spots on heater coils, the Xceed system also reduce NOx emissions more than 50% by diverting roughly half of the fuel to the Xceed nozzles.

In its first install of the new Xceed technology, XRG’s prediction models proved incredibly accurate, matching all simulated data for TMTs, BWT, and NOx.

Further improvement is possible with slight burner modifications.

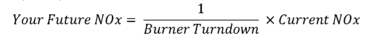

Estimate how much you can lower NOx with the Xceed System by trying this quick calculation:

Press Release: xrgtechnologies.com/vpr-xceed-system.

VPR Energy Case Study: vitol.com/case-studies/vpr-refinery.

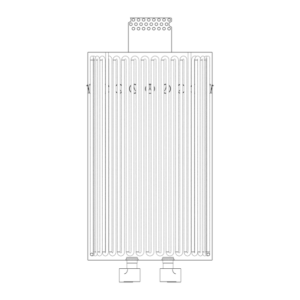

INTEGRATION INTO EXISTING HEATERS

The Xceed system has been designed to work with new or existing fired heaters. Our system is unique in that the firing ratio can vary between the conventional burners and the Xceed nozzles, depending on the project requirements and emissions goals.

A major benefit of the Xceed technology is that conventional burners stay in place. It is possible to revert to normal firing at any time, and startup and shutdown sequences remain the same. Specialized nozzles are placed in the wall of the heater and a portion of the fuel is mixed with flue gas and diverted from the burners to the nozzles. All the air still comes through the burners, so there is no complex switching between firing modes.

FREQUENTLY ASKED QUESTIONS

SMART APPLICATION

CFD models of before and after Xceed installation

When substantial CO2 and/or NOx reductions are needed, the Xceed system is the most economical option. While air preheater and selective catalytic reduction (SCR) will lower the NOx and CO2 emissions, they most often do not allow for increased firing capacity.

The Xceed system gives you all three, reducing the payback time and increasing the profitability of the unit.

We can walk you through the entire process, from an initial impact study to turnkey installation.

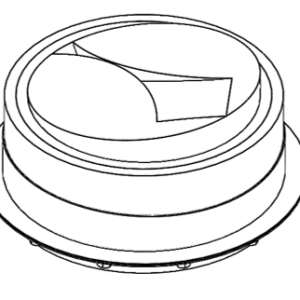

XCEED NOZZLES

Xceed nozzles injects fuel/flue gas at high velocity and rapidly mixes it with flue gas. The nozzle then overexpands the jet, mixing more flue gas and slowing the combined flow. Through computer optimization, XRG created a design that entrains more flue gas and mixes it more effectively than a round jet.

XCEED IN THE PRESS

Read our latest article here: Reducing CO2 and NOx while Increasing Efficiency from Fired Heaters without Selective Catalytic Reduction

Environmental, economic, and market forces require that fired heaters maintain or improve NOx emissions. XRG Technologies developed the Xceed system for dispersed combustion in fired heaters to address the problems associated with changing fuels, increasing efficiency without increasing NOx, and improving the heat flux profile. The flexible Xceed system can be retrofitted to existing heaters and allows for operation with zero-to-100% dispersed combustion for maximum reliability.

Listen to our podcast with Joe Batir from Energy Transition Solutions.

Bailey Hendrix, Matt Martin, and Erwin Platvoet discuss reducing inefficiencies and emissions in fired equipment. We end the discussion on our new technology, Xceed, which is meant to improve efficiency and lower carbon and GHG emissions from both new and existing fired heaters.