XRG Technologies uses cutting-edge computational fluid dynamics (CFD) as an integral part of our design process and to assist with troubleshooting and problem-solving in fired heaters.

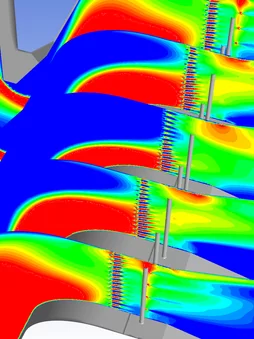

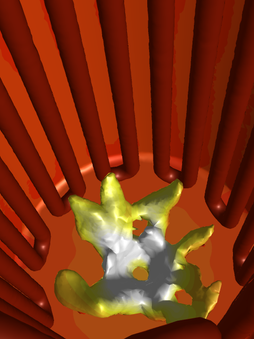

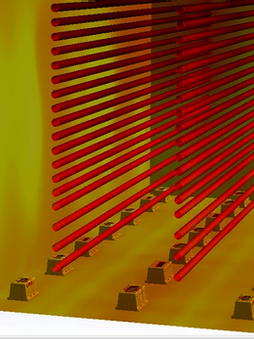

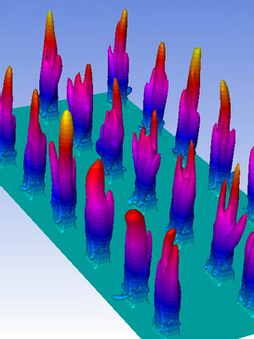

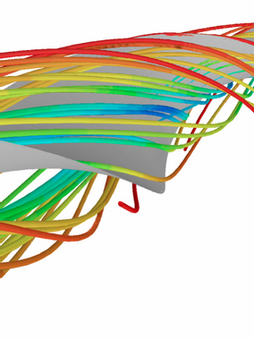

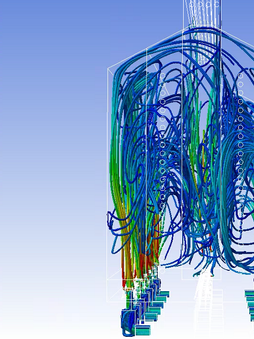

Computational fluid dynamic (CFD) is a simulation technology that performs detailed combustion analysis of burners in fired heaters to study the flow temperature profiles and the flue gas circulation pattern in the heater. The simulation defines the flue gas flow pattern, heat flux distribution over radiant tubes, tube metal temperatures, and temperature distribution in the heater.

Performing a CFD analysis on fired heaters allows XRG to study the current operating conditions to determine science-based solutions for problematic heaters.

“XRG provided a CFD evaluation of our St Charles Refinery Crude Heater Air Preheat System. This study included evaluation of the air and flue gas uniformity as well as the heat transfer and estimation of cold spots in the exchanger. The initial phases were carried out on schedule, provided comprehensive and easy to interpret results with credible conclusions. The current “what if” evaluations are being handled in a similar professional manner. I am happy with the efforts and would not hesitate using their CFD services in the future.”

We couple CFD results with commercial and proprietary thermal modelling software, and Finite Element Analysis (FEA), to provide detailed system analysis, including:

- Diagnose and solve flame impingement issues

- Evaluate burner configuration

- Analyze and improve heat flux

- Evenly distribute air flow between burners

- Identify flow induced vibration issues

- Solve corrosion issues caused by acid dew point

- Improve reagent distribution in SCR and SNCR systems

Breaking it down to basic engineering principles and truly understanding the fundamentals of fired equipment design and performance, the XRG Team excels in providing enhanced solutions to solve the greatest industry challenges.